BUILT FOR BEVERAGE FILLING & INJECTION MOLDING

The Changeover-First Scheduler

for High-Volume Filling Lines.

Changeovers destroy uptime. Taktora learns your real tribal constraints and generates production schedules that match floor reality.

Founded by alumni from

Not all changeovers are created equal

...and the worst ones shouldn't happen at all.

Current software thinks changes are just a simple penalty.

Operators don't, because they deal with the consequences.

Easy Rinse

Allergens, Requires full CIP

Never Let This Happen

Meet Taktora

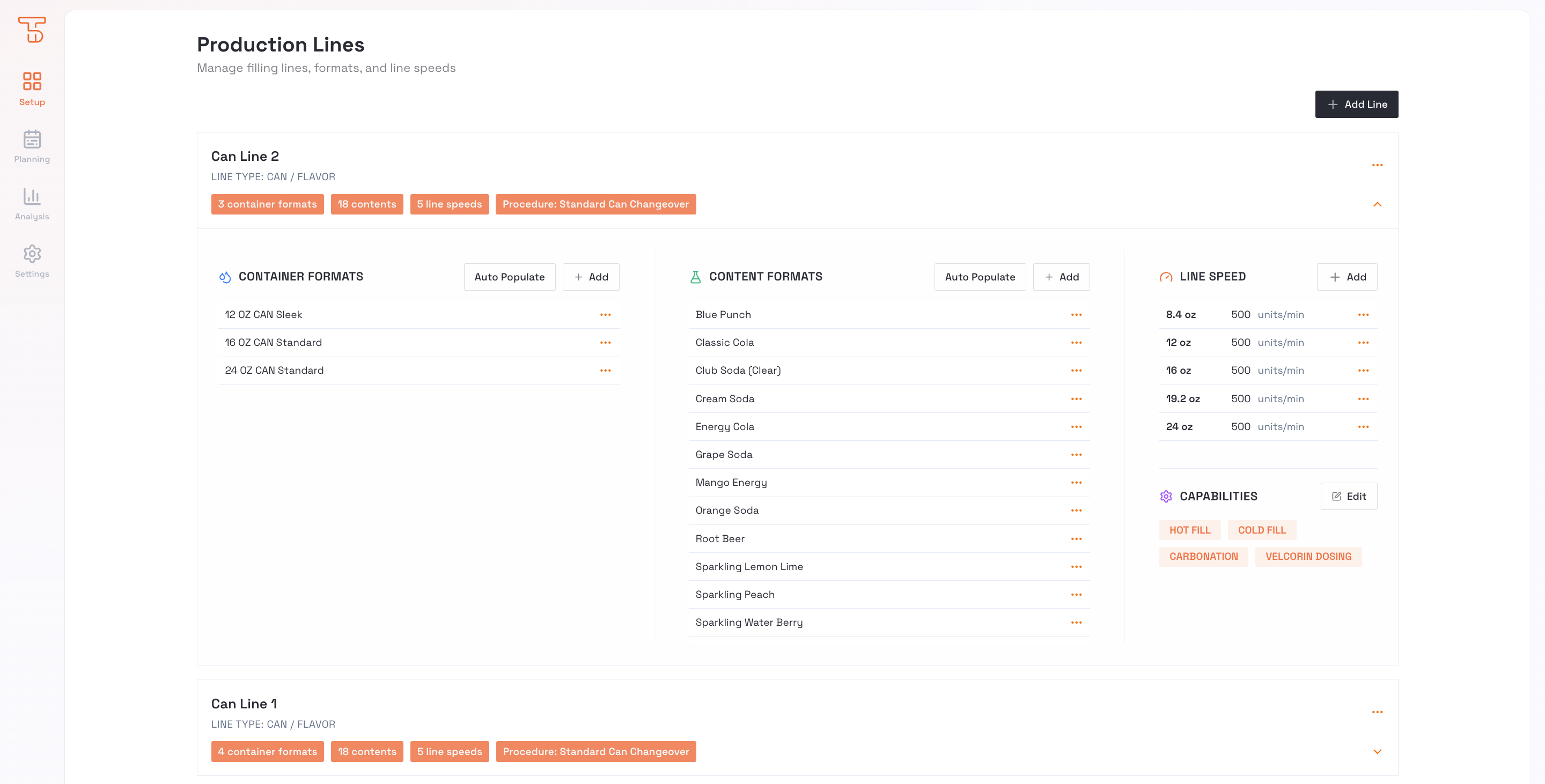

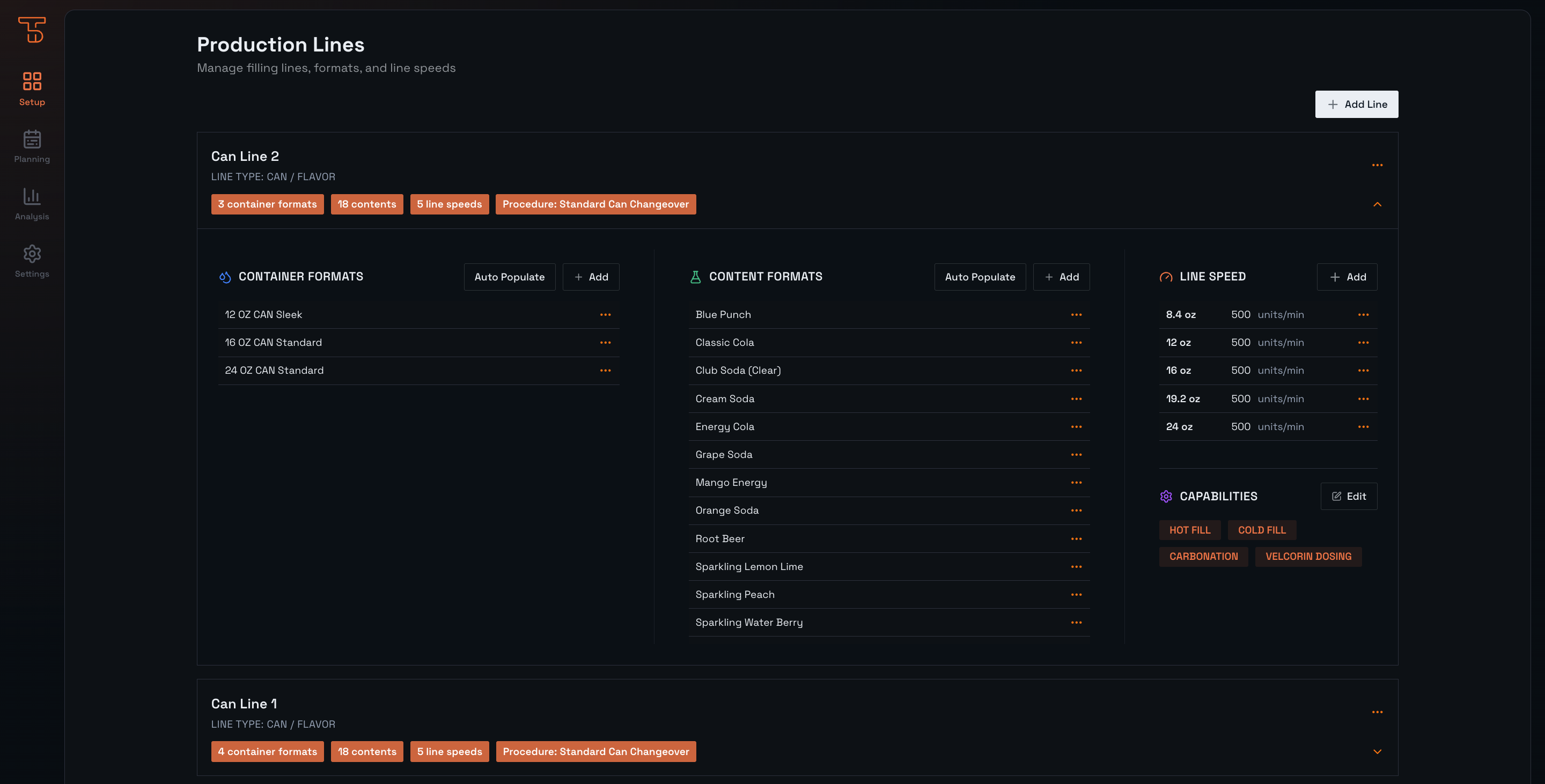

Taktora learns the real rules your operators use.

Then applies them across schedules, lines, formats, procedures, and jobs on your filling line.

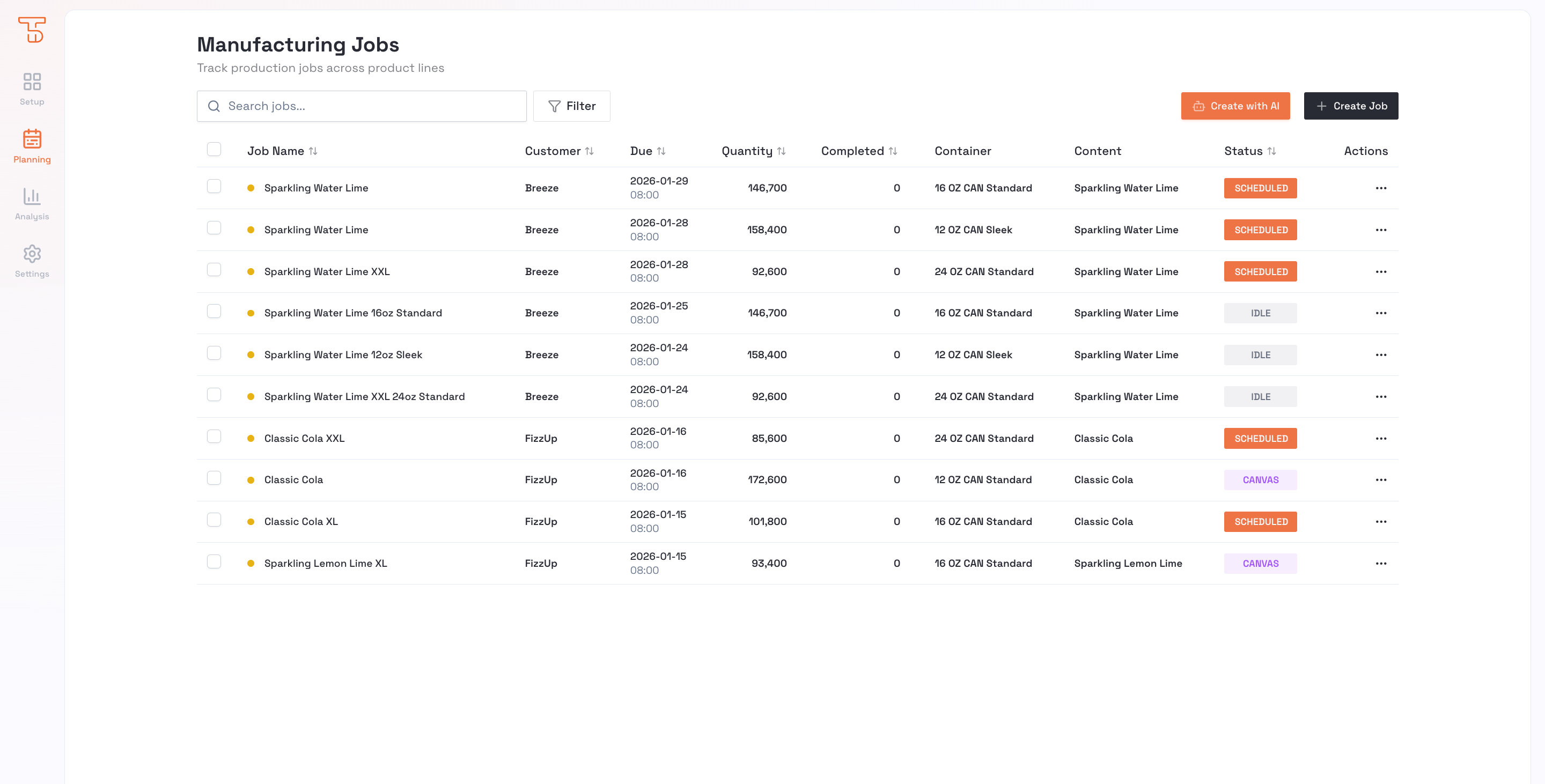

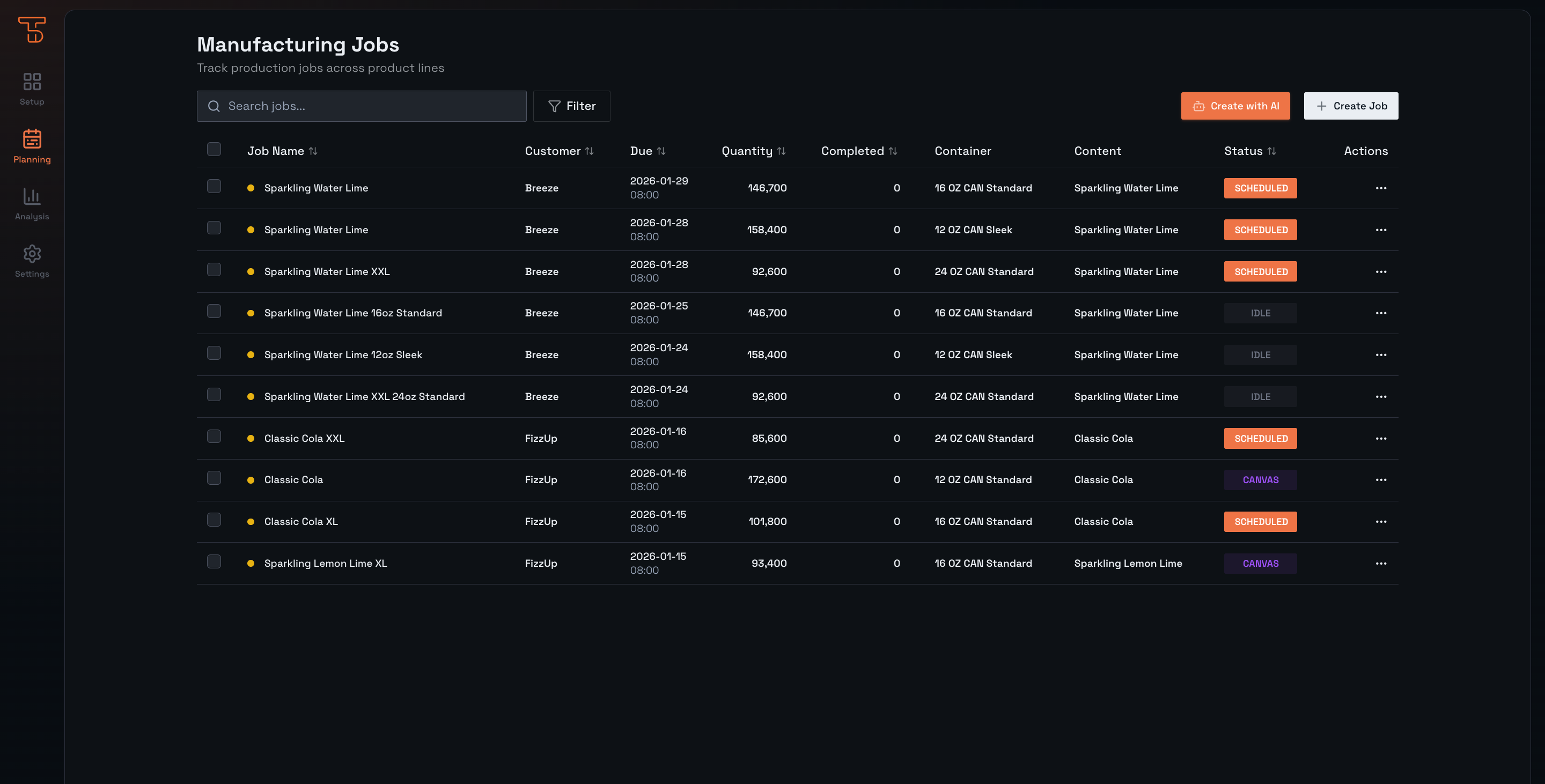

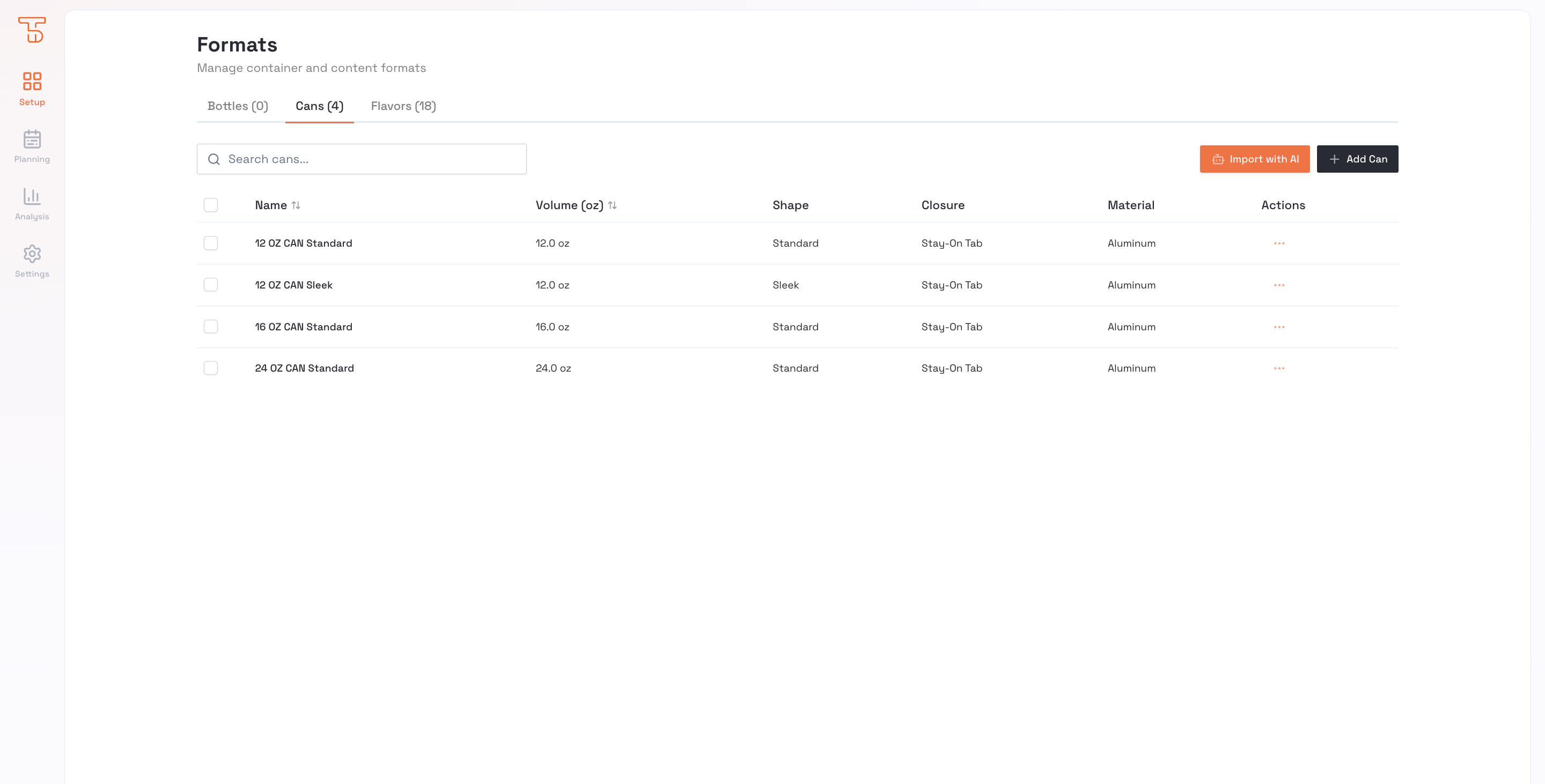

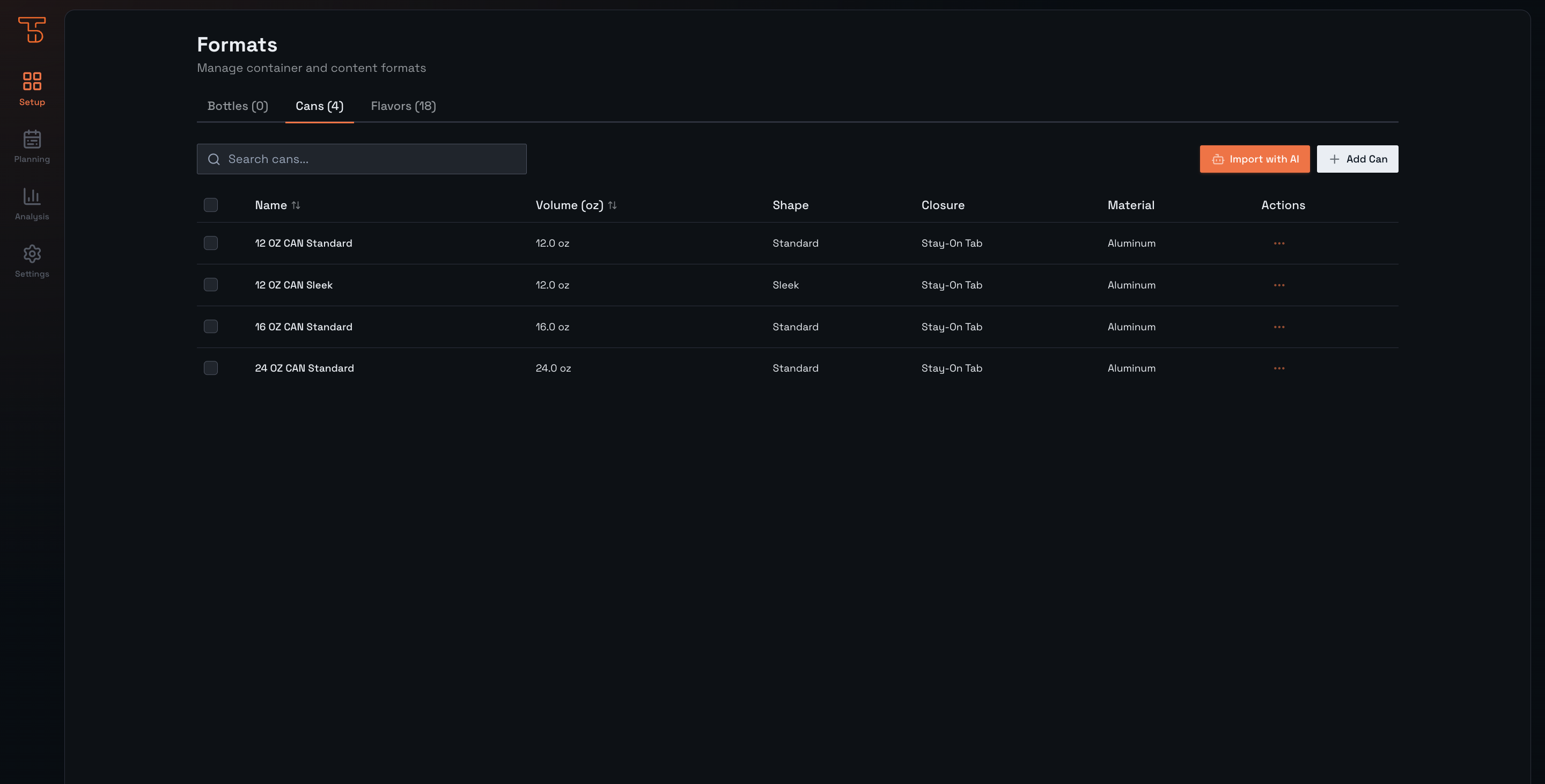

Turn messy jobs & PDFs into clean, schedulable data.

Our AI agents parse Excel Sheets, Invoices, and PDFs into ready-to-run production jobs — no more data wrangling.

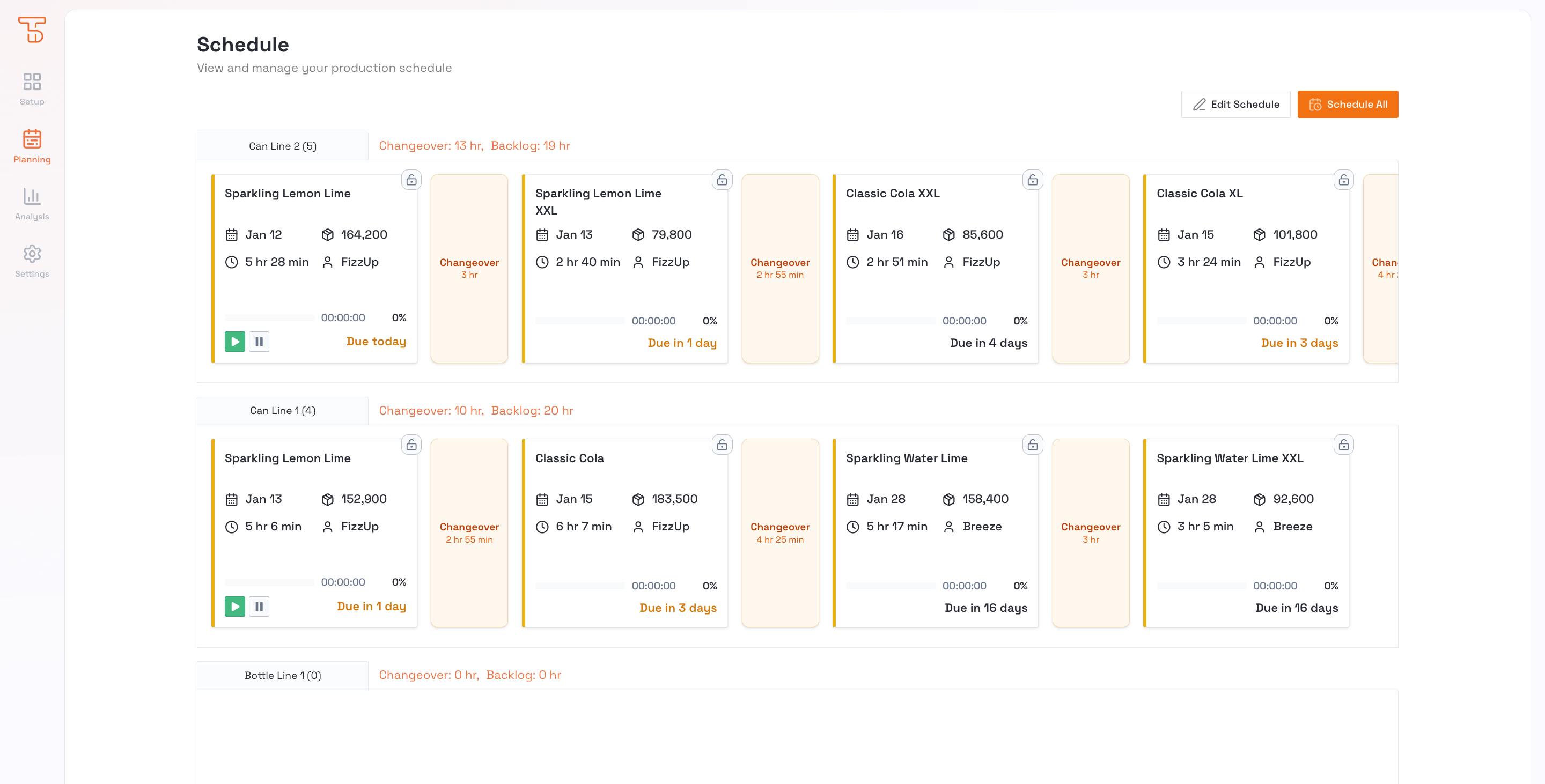

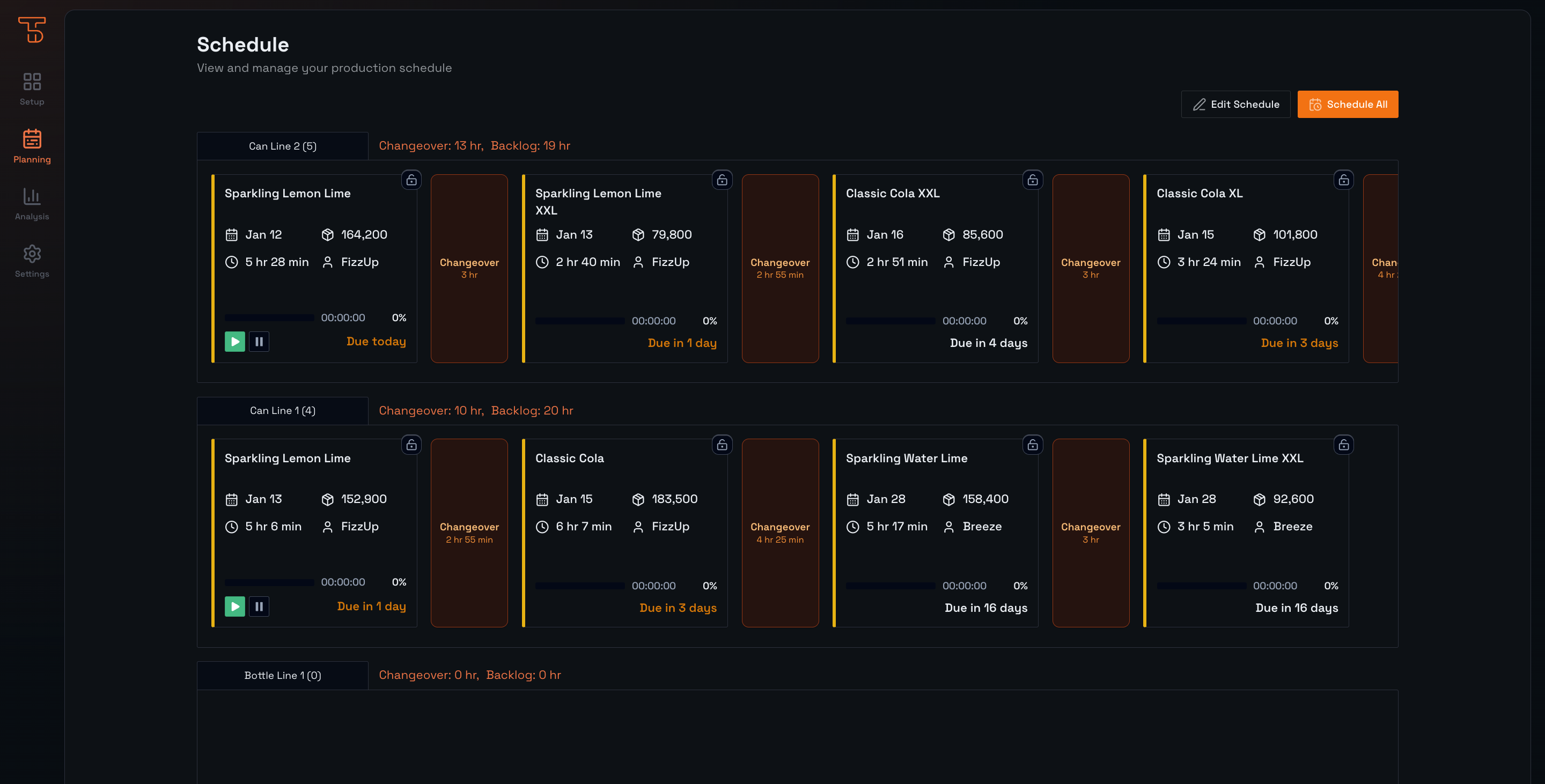

Generate a schedule operators actually trust.

Instantly produce an optimized sequence that respects constraints, reduces changeovers, and removes guesswork.

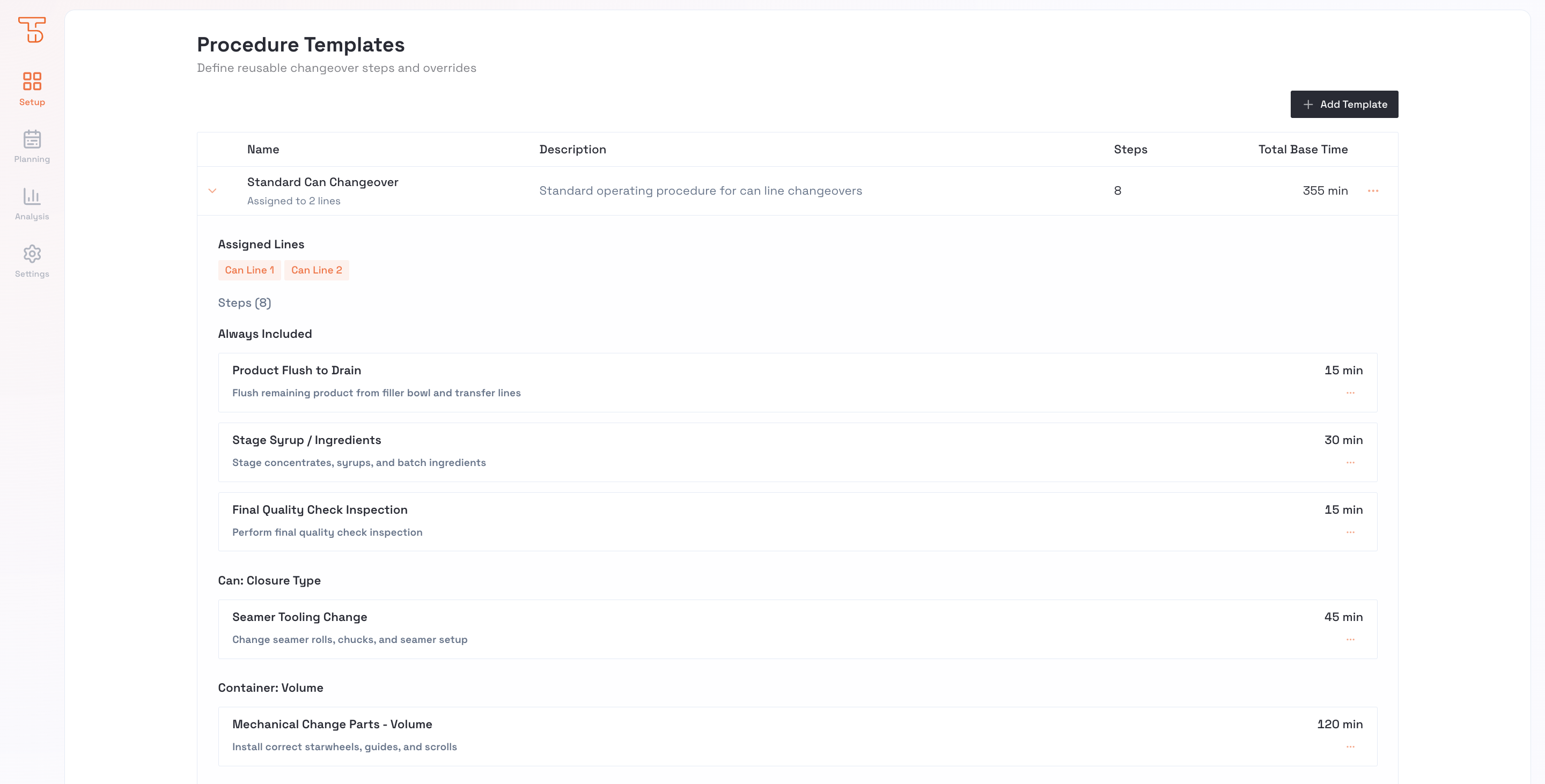

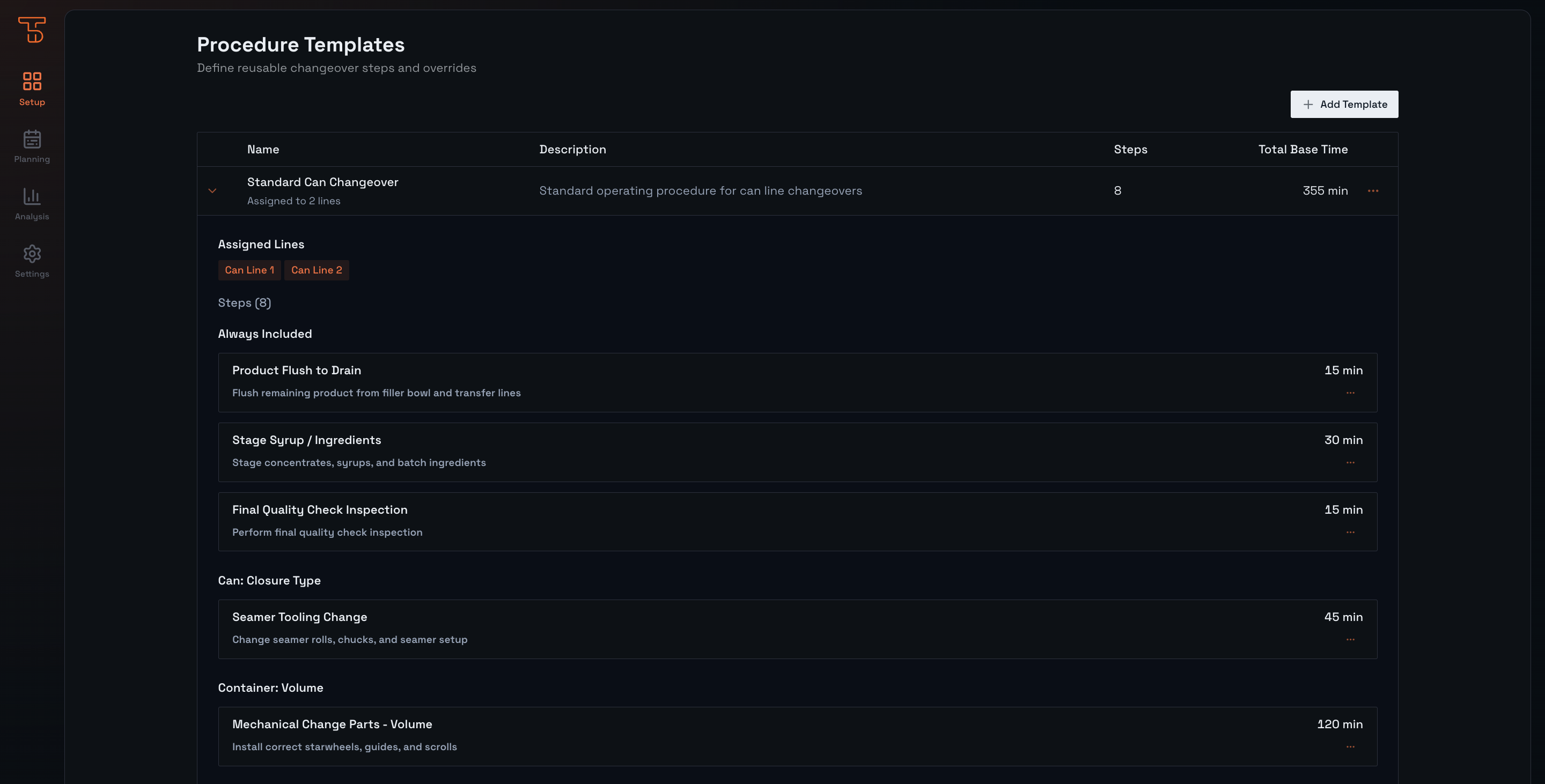

Handle changeovers & SOPs automatically.

Feed us your SOPs and our engine dynamically applies them to every job-to-job changeover.

Find the right plan for your needs.

Compare plans, then talk to us to tailor the right rollout.

Starter

For teams exploring Taktora.

Core features:

- Full Scheduling Engine

- Tribal Knowledge Engine

- Up to 50 formats (SKUs)

- Up to 50 jobs/mo

Starter plan includes:

- 1 production line

- AI Data Importer

- Standard analytics

- Email support

Standard

Perfect for smaller jobshops.

Core features:

- Full Scheduling Engine

- Tribal Knowledge Engine

- Unlimited formats (SKUs)

- Up to 300 jobs/mo

All Starter features and:

- 3 production lines

- Multi-shift calendars

- Approvals + RBAC

- Enhanced analytics

Professional

For factories with high SKUs.

Core features:

- Full Scheduling Engine

- Tribal Knowledge Engine

- Unlimited formats (SKUs)

- Unlimited jobs/mo

All Standard features and:

- 10 production lines

- Production Forecasting

- Full API access

- Scheduled Reports

- Priority support

Enterprise

Designed for growth at scale.

Core features:

- Full Scheduling Engine

- Tribal Knowledge Engine

- Unlimited SKUs & Jobs

- Unlimited Sites & Lines

All Professional features and:

- Private Cloud

- Custom ERP / MES Integrations

- Custom PLC / SCADA integrations

- On-prem hardware deployment

- Secure OAuth2 Client Access

Factory Floor Voices

Real challenges from manufacturing professionals who understand the pain points TAKTORA solves.

Manual data can be manipulated. We need granular, automated tracking of every production line metric to optimize our P&L calculations.

We only caught underfilled bottles at shift end. Instant defect detection would save hours of rework and prevent batch scrapping.

Excel scheduling breaks when unexpected events happen. When our factory head broke his arm, everything fell apart - lost inventory, delayed orders.

Rooted in 20+ years of real industry experience

and designed to work the way operators actually do.